The basic characteristics of bar steel grating

Jun 13,2025

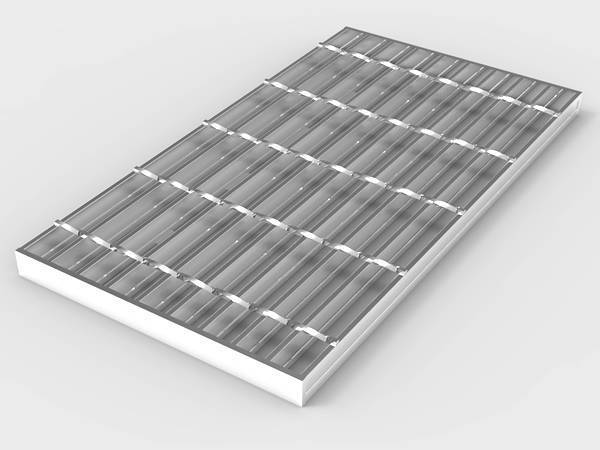

Reinforced steel grating (also known as steel grating plate or grating plate) is a grid-shaped steel product formed by cross-welding flat steel and cross bars, and is widely used in industrial, municipal and other fields. The following is the comprehensive information collation:

I. Basic Structure and Materials

Core components

Bearing flat steel : carbon steel (mainly Q235) or stainless steel (304/316), thickness 3-50mm, spacing commonly 30mm, 40mm or 60mm.

Crossbar : usually twisted square steel (twisted steel), mostly 6×6mm or 8×8mm, spacing 50mm or 100mm.

Surface treatment

Hot-dip galvanizing (mainstream process, with an anti-corrosion life of up to 20 years), electro-galvanizing, painting or no treatment (for stainless steel materials).

Ii. Core Performance Advantages

High STRENGTH LIGHTWEIGHT : Flat steel grid structure load-bearing (maximum compressive strength 300-1000 mpa), self-weight 30%-50% lighter than solid sheet.

Safety anti-slip : Serrated design or composite checkered plate, anti-slip coefficient > 0.7, especially suitable for oily and wet environments.

Ventilation drainage : Grid structure has 3 times higher permeability than concrete, effectively avoids water accumulation.

Corrosion resistance : Hot-dip galvanized to resist acid, alkali and salt spray, stainless steel for Marine engineering.

Iii. Main Application Scenarios

Industrial field

Platform walkways, equipment frames (such as those in power plants and chemical plants).

Stair treads and oil pit grates (with anti-slip tooth design).

Municipal Engineering

Drainage ditch covers (quick drainage and anti-clogging), pedestrian overpasses, manhole covers.

Transportation Energy

Airport runways, wharf platforms, bridge guardrails (resistant to dynamic loads).

Building decoration

Perforated curtain wall (light transmittance 30%-70%), indoor and outdoor stairs.

Iv. Derivative Types

Composite steel grating : Welded patterned steel plate on the surface for enhanced anti-slip performance, used for heavy equipment platforms.

Interlocking steel grating : No welding interlocking structure, stronger load-bearing capacity.

Toothed steel grating : Flat steel edge pressed teeth, better anti-slip performance.

V. Key Points of Selection and Construction

Load matching : Static load ×1.5, dynamic load ×2.0 safety factor design.

Installation method : welding (permanent) or bolted (detachable).

Environmental fit : Preferred 316 stainless steel for coastal/chemical areas; Hot-dip galvanized carbon steel for conventional environments.

Note : Reinforced geogrids are different from geogrids (such as steel-plastic composite geogrids), which are mainly used for roadbed reinforcement, non-metallic grid structures.

Contact Us